Lantos Technologies has developed an intra-aural 3D scanning device that allows dispensing professionals to take 3D digital images of the ear canal and provide manufacturers with a digital method for accurately creating customized hearing instruments.

Shahid Azim, MBA, founder and former senior vice president of Lantos Technologies, is a serial entrepreneur, and comes from a technology services background. His previous start-up was in the technology services market, which was acquired in 2007 by a leading financial services company. Azim is a graduate of MIT’s Sloan Fellow MBA program.

Although a large number of articles in HR, such as those from Chester Pirzanski,1-4 have been devoted to impression-taking, the entire process of rendering the exact replica of the dynamic ear canal remains inherently inconsistent and professionally demanding. Knowledge, skills, and experience need to be mastered prior to taking an ear impression on a patient. A number of different techniques and materials have been proposed, but the fact remains that there still isn’t one agreed-upon standard for impression-taking. The process remains something of an art, and some clinicians are better artists than others. These inconsistencies have almost certainly led to unnecessary time lost in preparing earmold materials and cleaning, multiple visits/fittings, and, in worst-case scenarios, discomfort for patients, frustration for dispensing professionals, and extra costs for hearing aid manufacturers (and consumers) in the form of hearing aid returns.

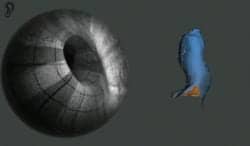

Figure 1. Lantos Technologies’ intra-aural 3D scanning device eliminates the need for taking physical ear impressions with standard impression material. Utilizing a handheld video otoscope/scanner that maps the interior of a liquid-filled conforming membrane (CM) inside the ear canal, the system is designed to take 3D images safely beyond the second bend.

For over a decade, there has been talk about digital scanning of ear canals and all the great benefits it can usher for key stakeholders. Now, Cambridge, Mass-based Lantos Technologies has developed an intra-aural 3D scanning device that eliminates the need for dispensing professionals to take physical ear impressions, while still providing an accurate image of the ear canal for manufacturers to create customized hearing instruments (Figure 1).

Hearing care professionals understand the implications of ear canal dynamics, correct oto-block (tamp) size, particularly when taking deep-canal impressions. In addition to the labor involved in making impressions, manufacturers are increasingly creating hearing aids that are “invisible,” and consequently there is a growing need for deeper and more accurate impressions that provide rich data for creating custom hearing products that fit comfortably.

There are many challenges to taking impressions beyond the second bend in the ear canal and obtaining impressions with appropriate detail. Dispensers routinely vary their use of up to four different types of (viscosity) shore value silicone, depending on the patient’s canal and the selected hearing aid, in order to render the best impression, and therefore capture as much data as possible for the manufacturer’s scanning of the final impression.5,6

Another challenge is when patients have very “active” ears, including those patients with temporomandibular joint (TMJ) syndrome.7-9 As Hall10 pointed out, “One of the greatest challenges for the dispensing professionals is to be able to successfully fit patients who have…TMJ syndrome or patients who have abnormally large movements of the TMJ that affect the dynamic ear canal.” Retention and feedback issues can be particularly frustrating for these patients. When making custom hearing protection, it is critical that canal dynamics are accounted for, since a loose seal nullifies their performance. This measurement of organic movement of the canal potentially presents the next frontier in determining fit and comfort of custom-made devices.

There is a side benefit to using silicone impression material and something the industry has grown to use fairly effectively. The fact that impression material presses against the canal walls provides a key data point to the manufacturer relative to compliance (elasticity) in the canal. The manufacturers all have their own unique templates to process this data point, but use it to oversize or undercut the shell at key areas to enable a comfortable fit.11

THE LANTOS TECHNOLOGIES SOLUTION

Figure 2. The handheld unit has two modes: video otoscope and digital scanner. The clear viewport allows for video otoscopy and inspection of the ear canal, as well as the precise placement of the conforming membrane at the exact depth required. Once placed, the CM is then filled with a solution of water and biocompatible dye. The scan button is pressed and the 3D scanner retracts, while taking digital images of the ear canal.

With the increase in the number of discreet, deep-canal hearing aids being introduced,12 it is an appropriate time to be introducing a safe digital method of mapping the entire ear canal—a process that can take ear canal dynamics and measure canal elasticity uniformly throughout the geometry.

Developed by Professor Douglas P. Hart at the Massachusetts Institute of Technology (MIT), Federico Frigerio, and the author, Lantos presents a simple and compact 3D ear impression solution. The approach resolves the aforementioned shortcomings of the current manual impression system with a 3D digital scanner capable of measuring static images, as well as ear canal dynamics and tissue compliance.

The Lantos solution also builds on the benefits of the existing process by replicating it in a controlled and measured way through inflating a membrane in the canal and enabling the system to capture canal elasticity. This method eliminates many of the risks and inefficiencies associated with the current manual impression process, enabling for the first time “end-to-end” digital manufacturing for custom devices and creating workflow efficiencies. It also improves the patient experience, and advances the science of hearing care by bringing new data to the forefront.

The Lantos system consists of a small portable handheld device that can capture 3D digital images of the ear canal in 60 seconds or less (Figure 2). The handheld device plugs into a laptop computer and provides seamless integration into the current workflow for hearing professionals. The 3D scan files, dynamic and compliance information, and electronic order forms can then be made available to any manufacturer almost instantaneously from anywhere in the world.

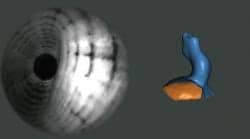

Figure 3. Through the clear viewport, the clinician can inspect the ear canal and ensure the proper placement of the tip of the conforming membrane.

Figure 4. Once the conforming membrane is filled with liquid, the optical scanner is slowly retracted inside the membrane.

Figure 5. The 3D digital impression is completed with the complete retraction of scanner inside the membrane.

The 3D imaging technology behind this scanner is a development of the Emission Reabsorption Laser Induced Fluorescence (ERLIF) technique13 and relies on the selective absorption of emitted fluorescent light. Using this technology involves inserting a disposable conforming membrane (CM) made of an extremely flexible and biocompatible silicone polymer into the ear canal. The CM has a clear viewport at its tip that enables the scanner to act like a high-end video otoscope while positioning the membrane in the ear canal (Figure 3). Through viewing this video feed, the clinician has full control for precise placement of the membrane at the desired depth in the ear canal.

Once the CM has been optimally placed, it is expanded to conform to the ear canal geometry using a solution of water and a biocompatible dye. At the press of a button, the scanner switches from video otoscope mode to 3D scanning mode and the optical tip automatically retracts inside the expanded membrane. It then takes hundreds of images along the length of the canal, concha, and helix (Figures 4-5). The system is able to generate a 3D digital scan from these images in real time using proprietary algorithms, allowing the dispensing professional and patient to watch the digital impression “grow” live on the computer screen. When the 3D scanning process is complete, the membrane is automatically deflated and the scanner can be comfortably and safely withdrawn from the patient’s ear.

The conformal membrane provides exceptional comfort and safety for the patient because the inflation pressure is low and because it is designed to only inflate radially and not medially toward the tympanic membrane. This allows for comfortable and safe deep-canal scans well beyond the second bend.

Figure 6. The system is compact, movable, and attractive.

Another key advantage of the CM is that it moves obstructions such as hair or soft cerumen out of the way as it pushes up snugly against the canal walls. Any artifacts caused by hard cerumen or crusting judged as inadvisable to remove may be noted on the scan and detailed out by the modeler at the lab. Cases of ear canals that have been surgically altered following mastoidectomy or fenestration, ear canals with osteomas or exostoses, or tympanic membrane perforations no longer present the risk of injury from impression material when the Lantos scanner is employed.

Another innovative feature of the system is that it can slightly vary the pressure uniformly inside the conformal membrane to show ear canal elasticity. As the CM is slightly expanded, the soft tissues are expanded by an amount proportional to their compliance. Canal elasticity and the precise localization of canal wall mobility are important new data sets for dispensing professionals and manufacturers as they personalize the fit. Hearing aid manufacturers will be collaborating with Lantos to provide the basic research and practical experience to turn this raw dynamic and elasticity data into valuable information that can be integrated into the manufacturing process.

CONCLUSION

The Lantos scanner brings digitization to impression taking, but it also allows the hearing professional to capture the exact location and extent of ear canal excursions caused by patient jaw movement. Assessment of ear canal dynamics will allow the design of an optimally shaped device that will provide an acoustic seal, remain securely in position in the ear, and be comfortable for the user over a wide range of physical activity.

Lantos plans to make their technology a platform that allows hearing professionals to send the scan data to any hearing aid manufacturer.

Correspondence to Shahid Azim can be addressed to HRP via .

References

- Pirzanski C. The anatomy of a perfect ear impression. Hearing Review. 1998;5(12):2-24.

- Pirzanski C. Factors in earmold style selection: Starting (and finishing) right. Hearing Review. 2001;8(4):20-24. Available at: www.hearingreview.com/issues/articles/2001-04_01.asp

- Pirzanski C. Earmolds and hearing aid shells: A tutorial, Part 2: Impression taking techniques that result in fewer remakes. Hearing Review. 2006;13(5):39-46. Available at: www.hearingreview.com/issues/articles/2006-05_10.asp

- Pirzanski C. Earmold retention issues: Why do these earmolds keep falling out? Hearing Review. 2010;17(5):26-34. Available at: www.hearingreview.com/issues/articles/2010-05_02.asp

- Cortez R. Changing with the times: Applying digital technology to hearing aid shell manufacturing. Hearing Review. 2004;11(3):30-38. Available at: www.hearingreview.com/issues/articles/2004-03_03.asp

- Sullivan RF. Why morphology matters: Practical dispensing applications of 21st century shell design technologies, Part 2: Practical applications and benefits for dispensing professionals. Hearing Review. 2008;15(3):38-89. Available at: www.hearingreview.com/issues/articles/2008-03_03.asp

- Oliveira R, Babcock M, Venem M. The dynamic ear canal and its implications. Hearing Review. 2005;12(2):18-19,82. Available at: /issues/articles/2005-02_01.asp

- Earmolds and hearing aid shells: A tutorial. Part 2: Impression-taking techniques that result in fewer remakes. Hearing Review. 2006;13(5):39-46. Available at: www.hearingreview.com/issues/articles/2006-05_10.asp

- Griffing TS, Giles GE, Romriell D. Relationship of TMJ & TMD to successful CIC fittings. Hearing Review. 1998;4(5):14-18.

- Hall CM. Clinical experience using a hearing aid for TMJ-related fitting problems. Hearing Review. 2004;11(4):50-53. Available at: www.hearingreview.com/issues/articles/2004-04_07.asp

- Pirzanski C, Berge B. Is the end near for acoustic feedback? Hearing Review. 2004;11(4):18-23. Available at: www.hearingreview.com/issues/articles/2004-04_01.asp

- Strom KE. A comeback of sorts for CICs? Hearing Review. 2012;19(4):6. Available at: www.hearingreview.com/issues/articles/2012-04_08.asp

- Hidrovo CH, Hart DP. Emission reabsorption laser induced fluorescence (ERLIF) film thickness measurement. Meas Sci Technol. 2001;12:467-477. Available at: tinyurl.com/84q8v58