Tech Topic | June 2021 Hearing Review

The effects of moisture on hearing aid repairs and electroacoustic performance are a well-documented and decades-old problem. There are now extremely effective tools available for controlling moisture-related malfunctions and performance issues. This article looks at the Redux system as a dedicated tool for professional drying services in a practice.

By Matt Hay, MBA

Hearing aids get wet. This is perhaps the hearing care industry’s worst kept secret. However, the negative effects of moisture on hearing aid performance are not always fully appreciated by hearing care professionals (HCPs) or consumers.

Understanding Moisture Problems

How do hearing aids get wet? We know hearing aids are expected to perform with incredible precision:

…for ~40,000 hours;

…on a planet covered mostly by water;

…while filled with humid air;

…surrounded by an organ (skin) that regulates body temperature with constant sweating, and

…in or behind an ear that produces sebum and cerumen.

Considering these environmental factors, a more reasonable question is “How do aids ever stay dry?” In his research, Agnew1 noted:

“The reliability and longevity of electronic devices is often linked to the environmental conditions in which they operate. Typically, the higher the ambient temperature and relative humidity (RH), the shorter the operating life. Hearing instruments are no exception.”1

In reality, the challenge among hearing care professionals has not been understanding the concept that moisture and electronics don’t mix; the challenge has been what to do about it. New drying technology and moisture measurement from Redux is designed to both quantify these moisture issues and offer a solution through proactive professional treatment.

Every hearing aid manufacturer is well-aware of moisture issues, and a steady stream of aids being returned by patients and customers for repairs keeps the concern top of mind. In the long run, this is good news for the hearing aid users, because that awareness has resulted in decades of effort to increase water resistance and protection.1-10

Nanocoating of hearing aid components slows the damage that moisture will eventually cause to the hardware.9 However, progress in in this area should not be confused with a solution. Nanocoating does not fully protect the hearing aid from moisture intrusion. In fact, efforts to keep moisture out of the aid can be counterproductive by keeping moisture inside the aid. Containing the moisture is only a partial solution, because any moisture that does get into the device eventually must be removed.

Ingress Protection (IP) ratings can be a helpful guide for measuring an aid’s resistance to solids and liquids.11 While manufacturers work toward higher IP ratings with hearing aids, it is important to understand some limitations of this scale. Specific rating levels are requested and then measured under laboratory conditions with “clean” water rather than a real-world environmental factor, such as sweat or rain (or the inadvertent shower or pool plunge). These IP ratings are not certified and may not reflect an intended use. For example, humidity exists as a vapor, allowing it to pass through many water-resistant barriers and then condense inside a hearing aid when the temperature changes (eg, much like glasses fog up when moving from a cold to a warm place).

Despite these improved moisture resistance efforts, new HCP survey data12 from HearingHealthMatters and Redux suggests it remains a significant issue for patients and practices:

- About half of aids are returned while under warranty.

- 67% of aids are returned multiple times after warranty.

- HCPs report wax/moisture as the leading cause of hearing aid malfunction.

- 73% of offices spend more than an hour per day (25% spend more than 3 hours/day) manually cleaning/drying aids.

- 98% of hearing aids have moisture present.

- Moisture presence is a not just seasonal.

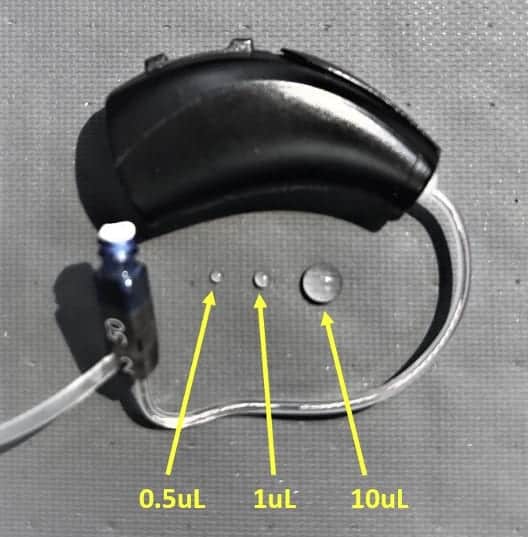

Redux testing has shown that as little as 0.5 microliters of water in the receiver can have as much as a 30 dB impact on an aid’s performance (Figure 1). For perspective, 0.5 uLs of water is to an ITC aid what three bathtubs of water is to the volume of an average-size US home.

Understanding Moisture Solutions

In 2010, Hall and Croutch8 conducted a field study on the impact of humidity on aids. Their research concluded by noting that patients with “moisture and receiver problems should be counseled as to the importance of taking proactive measures to reduce potential frustrations with the device.” They went one to add, “It is our hope that these findings will lead to additional research and possibly the development of better equipment to deal with this problem.”8

In 2013, Reuben Zielinski and and Joel Trusty introduced the Redux drying system for saving wet cellphones in more than 2,000 Verizon Wireless stores across the United States. To date, more than 2.5 million wireless subscribers count on Redux to save their phones and data in the event of moisture damage. Zielinski’s past role as director of research and development at Songbird Hearing13 made him very knowledgable about the need for improved drying methods for hearing aids. Using a combination of vacuum chamber and heat technology, Redux hardware reduces chamber pressure to lower the evaporation point of water. The system then safely applies controlled heat to speed up the evaporation process without danger to the hearing aid. Meanwhile, an internal humidity sensor measures and reports the amount of moisture removed during the heated vacuum cycle. This process is repeated until the sensor measures that the chamber and its contents have reached a state of complete dryness.

Other over-the-counter “dehumidifier” products have existed for years. Applying enough airflow and heat for a long enough period of time will likely remove some or most of the moisture from within a hearing device. Redux is not intended to be a replacement for the at-home drying boxes any more than a toothbrush should replace a dental visit. It is a professional, in-office service provided to patients by hearing care practices (think dry cleaners versus an at-home washer and dryer). Redux differentiates itself as a service by providing complete moisture removal with the amount removed verified in real-time during each treatment. This is operationally possible for the HCP office because the entire process takes only about 8 minutes.

Redux partners have the option of completing a 2-question check-in and check-out with each treatment. Based on nearly 20,000 drying treatments across North America, Australia, and Europe, practices report the following outcomes:

- “Dead” Hearing Aid Improvement Rate: 50%

- “Weak” Hearing Aid Improvement Rate: 83%

- “Good” Hearing Aid Improvement Rate: 80%

- Total Hearing Aid Improvement Rate: 77%

- Treatments Showing Moisture Removed: 98%

The end-user data reinforces the point that a level of moisture is present in nearly all treated aids, implant processing units, and hearables. Dead or weak aid recovery supports the theory that moisture is a common and avoidable cause of malfunction. The high rate of improvement among aids reported as “good” prior to Redux treatment is remarkable, as it highlights the presence of slow degradation in aid functionality that may happen imperceptibly over time (like hearing loss!).

This supports the need for proactive and preventative moisture removal. Similar to changing car oil every 3,000 miles to avoid engine failure, an aid is more likely to retain proper function with regular drying.

As hearing healthcare continues to move toward a more patient-centered approach to care, keeping hearing aids dry should be considered a part of that process. When aids sound better and require fewer returns, patients have better experiences. Conversely, frequent repairs result in a significant cost to a patient and practice in terms of time. At the 2020 ADA virtual convention, Robert Traynor, EdD, estimated the time cost per manufacturer return to be $263.14 This cost to the practitioner includes checking the device, fitting a loaner aid, completing paperwork/packaging, rescheduling, verifying repair. and refitting the new aid. Removing all moisture in 8 minutes with a push of a button represents a significant opportunity to improve the patient experience while reducing the time cost to an office. Cliff (“Dr Cliff”) Olson, AuD, notes wax and debris cleaning is also faster after all moisture has been removed from an aid.

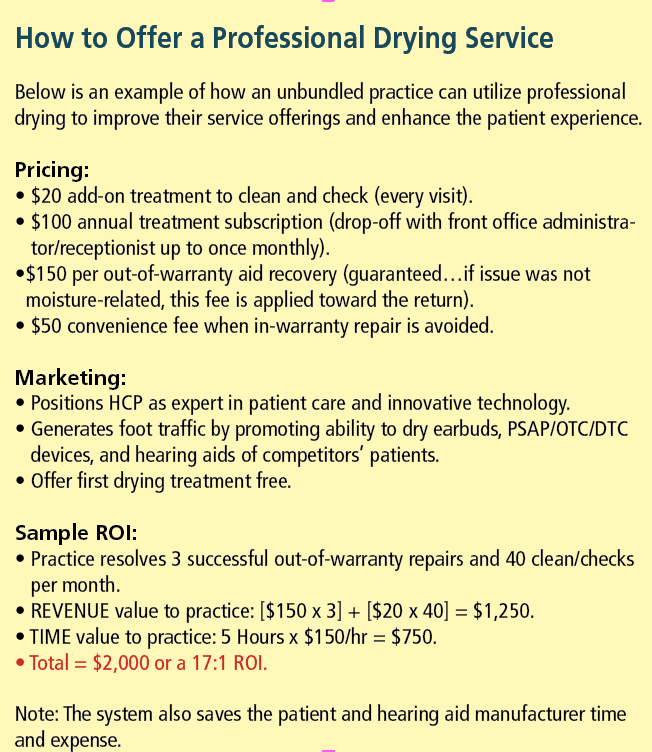

Professional treatment with Redux represents a revenue opportunity for hearing care professionals as well. Current users include bundled and unbundled private practices, ENTs, hospitals, and schools with each of these using Redux to see a positive ROI as a goal. The treatment is best offered proactively rather than waiting for an issue to arise with an aid. Partners are offering professional drying to patients as a pay-per-use service, on a subscription basis, an out-of-warranty repair avoidance tool, and incentive to purchase premium bundled or extended warranty offerings.

Redux is available to be rented ($115/month, with a 2-year agreement), purchased ($3,600), or rent-to-own at the following retail prices (note that there may be industry partnerships that could qualify a practice for below-retail rates). Either option includes free shipping, free training, a 30-day trial, and requires no additional software (any updates while under warranty are made remotely).

Following a uniquely challenging 2020 and the ever-looming question of the impact of eventual OTC legislation in the coming year, many practices are looking to provide added services that benefit their patients and their bottom line. Reducing or even eliminating moisture issues in aid through proactive care addresses both of these needs. As with any new technology, there is an adjustment period within the industry. Some professionals will seek to be first movers while many others take a more conservative watch-and- wait approach. Redux provides some objective measure and partner survey results to address the latter. With a few years and tens of thousands of aids improved, Redux has seen a 100% trial conversion rate in 2021 among offices that have tried Redux and undergone best-practices training to fully understand the service the system provides. The following results from active private practice accounts highlight positive feedback when asked about revenue, patient experience, ease of use, and willingness to recommend to other HCPs.

The professional drying service may not be a fit for every practice but there appears to be little downside to trying it. If hearing care professionals are genuinely committed to improving the lives of patients and increasing the value of the practice’s services, staying aware of new insight, new technology, and new solutions has never been more important in this ever-changing industry.

Correspondence to Matt Hay at: [email protected].

Citation for this article: Hay M. Moisture impact on hearing aids: benefits of proactive care by hearing care practices. Hearing Review. 2021;28(6):16-19.

References

- Agnew J. Temperature and relative humidity inside an ITE hearing instrument. Hearing Review. 1999;6(8):28-73.

- Bruener RC, House L. Thermodynamics of the external auditory canal. Temperature and relative humidity inside an ITE hearing instrument. Ann Otol Rhinol Laryngol. 1967;76(2):409-413.

- Bailey JW, Valente M. Measurements of relative humidity and temperature in hearing aids. Hear Jour. 1996;49(10):59-63.

- Knott B, Kochkin S. A moisture resistant switch for improving the robustness of BTEs. Hearing Review. 2003;13(4).

- Gray RF, Sharma A, Vowler SL. Relative humidity of the external auditory canal in normal and abnormal ears, and its pathogenic effect. Clin Otolaryngol. 2005;30(2):105-111.

- Branda E, Chalupper J. A new system to protect hearing aids from cerumen and moisture. Hearing Review. 2007;14(4):56,89.

- Moisture-proof toggle switch. Hearing Review. https://hearingreview.com/miscellaneous/moisture-proof-toggle-switch. Published March 14, 2008.

- Hall CM, Croutch C. A field study on the effect of relative humidity on hearing aid receivers. Hearing Review. 2010;17(1):32-35.

- Coulson S. Hearing aid component protection. Hearing Review. 2010;17(4):52.

- FDA approves waterproof cover for cochlear implant processor. Hearing Review. https://hearingreview.com/hearing-products/implants-bone-conduction/cochlear-implants/fda-approves-waterproof-cover-cochlear-implant-processor. Published December 15, 2014.

- Chalupper J, Flores A. Beneath the surface: Understanding the terms ‘water resistant’ and ‘waterproof.’ Hearing Review. 2011;18(11):56-61.

- Hearing Health & Technology Matters (HHTM) website. Hearing aid repair survey results. https://hearinghealthmatters.org/hearingnewswatch/2020/hearing-aid-repair-survey-results/. Published May 19, 2020.

- Cook JA, Preves DA, Grabowski DT. Real-ear measures for a disposable hearing aid. Hearing Review. 2001.

- Traynor R, Citron III D, Bray V. Amplify your impact: Personal styles and learning to listen. Presented at: AuDacity 2020 Academy of Doctors of Audiology (ADA) Virtual Convention; Oct 16-17, 2020; virtual.