|

| Brad Witt |

Since the publication of the Occupational Safety and Health Administration (OSHA) Hearing Conservation Amendment1 in 1983, numerous studies in the workplace have compared the real-world performance of hearing protectors to the laboratory-generated attenuation ratings of those same earplugs. Not surprisingly, many studies conclude that real-world attenuation is less than the published Noise Reduction Rating (NRR) for many workers. This difference has been attributed to a variety of possible causes, including the following:

- Lack of proper training in correct insertion of hearing protection.

- Workers intentionally sacrificing attenuation in order to enhance comfort.

- Earplugs that are poorly sized for a given worker.

- Hearing protectors that (unbeknownst to the wearer) simply do not conform to the personal anatomy of that user’s ear.

Compounding the discrepancy between real-world and rated attenuations is the fact that NRRs are simply population estimates. Hearing protectors are tested with a small sample of 10 subjects in an acoustic lab, and the mean results of that small sample determine the NRR of a product. A safety manager who provides hearing protectors with an NRR of 25 decibels to his noise-exposed workers should realistically expect some of his workers to obtain more protection, but most workers to obtain less protection, than the published NRR.

|

| FIGURE 1. Shows the difference in attenuation between two fittings of the same earplug in the same worker’s ear on the same day—about 10 minutes apart. In both cases, the earplug was in the ear far enough to satisfy a cursory visual inspection. The difference shown is enough to cause a 30-to 40-decibel improvement in attenuation at most frequencies when the earplug is deeply inserted and achieves a good seal in the ear canal. (Data from Howard Leight Acoustical Test Lab, San Diego) |

This disparity between real-world and rated attenuation is more pronounced in earplugs than earmuffs, for obvious reasons. There is simply more that can go wrong with the fit of an earplug. The insertion may not be deep enough. The diameter of the earplug may not effectively seal the ear canal. Or that particular wearer may have a bend in the ear canal preventing a full-contact fit with the ear canal walls. In all of these cases, attenuation is significantly degraded.

Figure 1 shows the difference in attenuation between two fittings of the same earplug in the same worker’s ear on the same day—about 10 minutes apart. In both cases, the earplug was in the ear far enough to satisfy a cursory visual inspection. But the difference shown in the graph—a good insertion versus a poor insertion—is enough to cause a 30 to 40 decibel improvement in attenuation at most frequencies when the earplug is deeply inserted and achieves a good seal in the ear canal.

In an attempt to bridge the gap between real-world and rated attenuations, a variety of NRR de-rating schemes have been proposed, reducing the NRR by 25% to 70%, for example.2 Others have proposed changing the testing methodology of hearing protectors, so that it automatically de-rates hearing protectors for real-world use by using naive test subjects. But critics of these de-ratings note that the problem is not the hearing protector; rather the problem is the wearer. If users could be trained to use the protectors correctly, then the real-world attenuation would approximate the rated attenuation for most users.

|

| FIGURE 2. Scattergram showing field attenuation of 100 workers at eight companies. Nearly two-thirds of the workers achieved attenuation within ±5 decibels of the published NRR for their particular earplug. (Data from Howard Leight Acoustical Test Lab, San Diego) |

VERIFICATION OF ATTENUATION

Several new tools now allow accurate measurement of real-world attenuation, rather than relying on population estimates of attenuation. Four systems now available on the market measure attenuation using quite different test methods, yet each produces an accurate indicator of the fit effectiveness of an earplug. The four methods used are as follows:

- Real-Ear Attenuation At Threshold: Test signals are presented at threshold, with and without earplugs. The difference between the two tests simply tells how much protection is offered by the earplug.

- Real-Ear Attenuation Above Threshold: Same as above, but test signals are presented above threshold using a simple loudness-balance procedure. Users can wear any earplugs, and there is no need for a quiet test booth.

- Microphone In Real-Ear: A probe microphone is inserted into specially modified earplugs. Users don these test earplugs, and listen while a loud noise sample is played. Software then calculates the amount of predicted attenuation.

- In-Ear Dosimetry: A probe microphone is inserted into specially modified earplugs. These microphones connect to miniature dosimeters (one for each ear) to monitor actual noise exposure under the hearing protectors.

The first three methods produce a Personal Attenuation Rating (PAR) for a specific wearer using a particular earplug at that moment in time. This rating is user-specific, ear-specific, and product-specific. These methods provide a snapshot indicating the capability of an earplug to protect against noise. But a worker might refit the protector quite differently 5 minutes later and walk into the hazardous noise.

Unlike the first three methods, In-Ear Dosimetry is a measurement of real-world noise dose over an entire work shift. It provides real-time continuous monitoring throughout the workday, and warns the worker when noise dose exceeds safe limits. In essence, the first three methods measure the capability of an earplug at a given moment, while the fourth method measures the worker’s protected noise exposure (under the earplugs).

|

| Designed to keep workers connected to their environment without compromising protection, Howard Leight’s new Clarity multiple-use earplugs improve worker safety and communication by blocking hazardous noise while allowing voice and signal frequencies to be heard more naturally. Designed for long-term comfort, Clarity incorporates a multimaterial design and translucent stem with an SMT membrane to regulate the transmission of sound frequencies through the earplug and ear canal. Its FlexiFirm core facilitates insertion, and a quadruple SoftFlange seal helps ensure proper fit. |

FIELD VERIFICATION RESULTS

These verification tools have shown some valuable results in field studies of attenuation. In one study, the real-world attenuation of earplugs worn by 100 noise-exposed workers at eight different noisy companies was measured. Workers wore a variety of earplugs from several different manufacturers. Figure 2 shows the attenuation results of these 100 earplug users. One-third of the tested workers achieved real-world attenuation that was equal to or higher than the published NRR for their respective earplug. The middle third of workers achieved attenuation within 5 decibels below the NRR, and the bottom third of workers showed real-world attenuation anywhere from 5 to 30 decibels below the NRR.

These workers were then interviewed to determine which factors correlated the best to a good earplug fit. The results showed there were no personal factors that were accurate predictors of a good fit of an earplug in the field: gender, age, ear canal size, years in noise, and familiarity with earplug model were simply poor predictors of whether a user would achieve good attenuation.

But when program factors were evaluated to predict good earplug fit, there was one factor that proved to be the strongest indicator of high attenuation in the field: one-on-one training. If a worker had received one-on-one training in how to properly fit an earplug, there was a high probability that worker would achieve good attenuation from their chosen earplug.

This positive effect of training held up only when the training was administered one-on-one. The same could not be said for group training sessions. In hearing protection, it seemed to make little difference whether the worker had participated in group training sessions of two or 20. But a single one-on-one training session significantly improved the probability of good protection.

IMPROVING THE PERSONAL ATTENUATION RATING

For workers who achieve a low PAR, two follow-up actions are recommended:

- Retrain them in proper insertion method;

- Select a different protector.

|

| Comparison of an improper fit of a foam earplug and a proper fit. Although the earplug is in place in both ears, the earplug shown on the left can have significantly lower attenuation (30 to 40 decibels across most frequencies) when compared to the earplug with a good fit. |

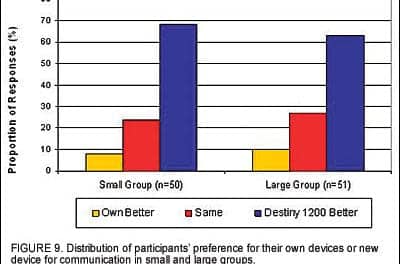

To determine whether a different protector really makes a difference, workers with poor attenuation results were invited to try a second pair of earplugs—usually a model they had never tried previously. Workers who tried a second pair of earplugs (with no additional training) often had major leaps in attenuation, bringing them closer to the rated attenuation.

This confirms the wisdom in OSHA’s requirement to offer a “variety of suitable hearing protectors” to noise-exposed workers. Some workers will simply never achieve satisfactory attenuation with one particular model of earplug. And if that earplug is the only choice offered at the worksite, some workers are destined for perpetual underprotection. Offering a second choice of suitable earplugs significantly improves the probability of more workers obtaining adequate protection.

|

| VeriPRO™ technology by Howard Leight makes it possible for safety managers to ensure employees are getting the most out of their hearing protection devices. VeriPRO measures real-world attenuation of unmodified earplugs and can be used as a means to improve individual employee training and enhance the overall effectiveness of Hearing Conservation Programs. |

BENEFITS OF FIELD VERIFICATION

Field verification systems require additional time for testing, beyond the time required for annual audiometric testing. But the rewards to employer and employee alike are significant:

- Attenuation testing provides a documented measurement of adequate fit (rather than just an estimation using the NRR).

- Workers can try several different earplugs, and select the model that provides the most comfortable protection.

- Overprotection can be measured and identified, thus improving communication with coworkers and warning signal detection.

- Studies indicate that Personal Attenuation Ratings are “sticky” in terms of being memorable to workers. Sixty days after one-on-one training, most workers can still recall the results of their earplug fit test, including the best-fitting protector.

- Several field test sites observed self-perpetuating peer training going on. That is, workers who had undergone attenuation testing and one-on-one fit training often demonstrated their good fitting practices to other workers.

- Fit-testing of earplugs provides immediate feedback to wearers. Users know right away whether their fit is acceptable or not, and can make immediate adjustments. And most importantly, it provides positive reinforcement that the hearing protection is doing its job, when worn properly.

In the past, safety managers lacked the tools to individually identify and correct poorly fit hearing protection. But field fit-testing now allows us to verify the amount of hearing protection offered, and take corrective action with those workers who might be unprotected.

Brad Witt is Director of Hearing Conservation with Sperian Hearing Protection LLC, San Diego.

REFERENCES

- Occupational Noise Exposure; Hearing Conservation Amendment; Final Rule. 29 CFR 1910.95 Federal Register. 46(162).

- Criteria for a Recommended Standard–Occupational Noise Exposure, Revised Criteria. Cincinnati: US Department of Health and Human Services (NIOSH). Pub No. 98-126.